Complete Metal Protection is Geelong’s go-to abrasive sandblasting and protective coatings provider for heavy engineering, structural steel, pipework and an assortment of other fabrication industries. We build and maintain strong relationships with our customers by providing the highest standards of quality, service and integrity.

We take quality seriously.

Procedural systems are in place for all areas of our operations and our experienced, conscientious staff deliver the highest degree of workmanship. (more…)

At Complete Metal Protection we know that having a high-quality, durable coating that protects your metal fabrication all depends on how the surface is prepared beforehand. This is where choosing the appropriate abrasive blasting media is critical. Complete Metal Protection provide professional and industry leading abrasive blasting services for a variety of industries Victoria-wide.

If you need a highly coarse media that delivers a deeper depth profile, achieving the anchor pattern that is so important before coating steel, then our Geelong-based sandblasting abrasive services are for you.

On other hand, if you’re working with a softer metal such as aluminium and do not want to damage or scratch the surface through the use of highly abrasive materials, then our glass bead blasting service would be the ideal choice for you.

Whatever your project, if you need abrasive blasting, Complete Metal Protection have you covered. Our highly talented team, state-of-the-art equipment and dedication to the highest quality of workmanship mean you can rely on us to get the job done, big or small.

Our team currently offer the following abrasive blasting services Victoria-wide:

Complete Metal Protection has equipment that enables us to work on large industrial projects this includes two 5t gantry cranes, a 5t yard crane, a 12t forklift, three 2.5t forklifts, 2 mobile diesel compressors, 3 electric compressors. This combined with our team of experienced and highly trained abrasive blasting specialists and large blasting shed allows us to deliver large-scale projects without compromising on quality.

To determine freight costs, please get in contact with our friendly team.

All stages of the blasting & painting processes are closely monitored, inspected and tested to ensure all specifications are met and quality is of the highest standard.

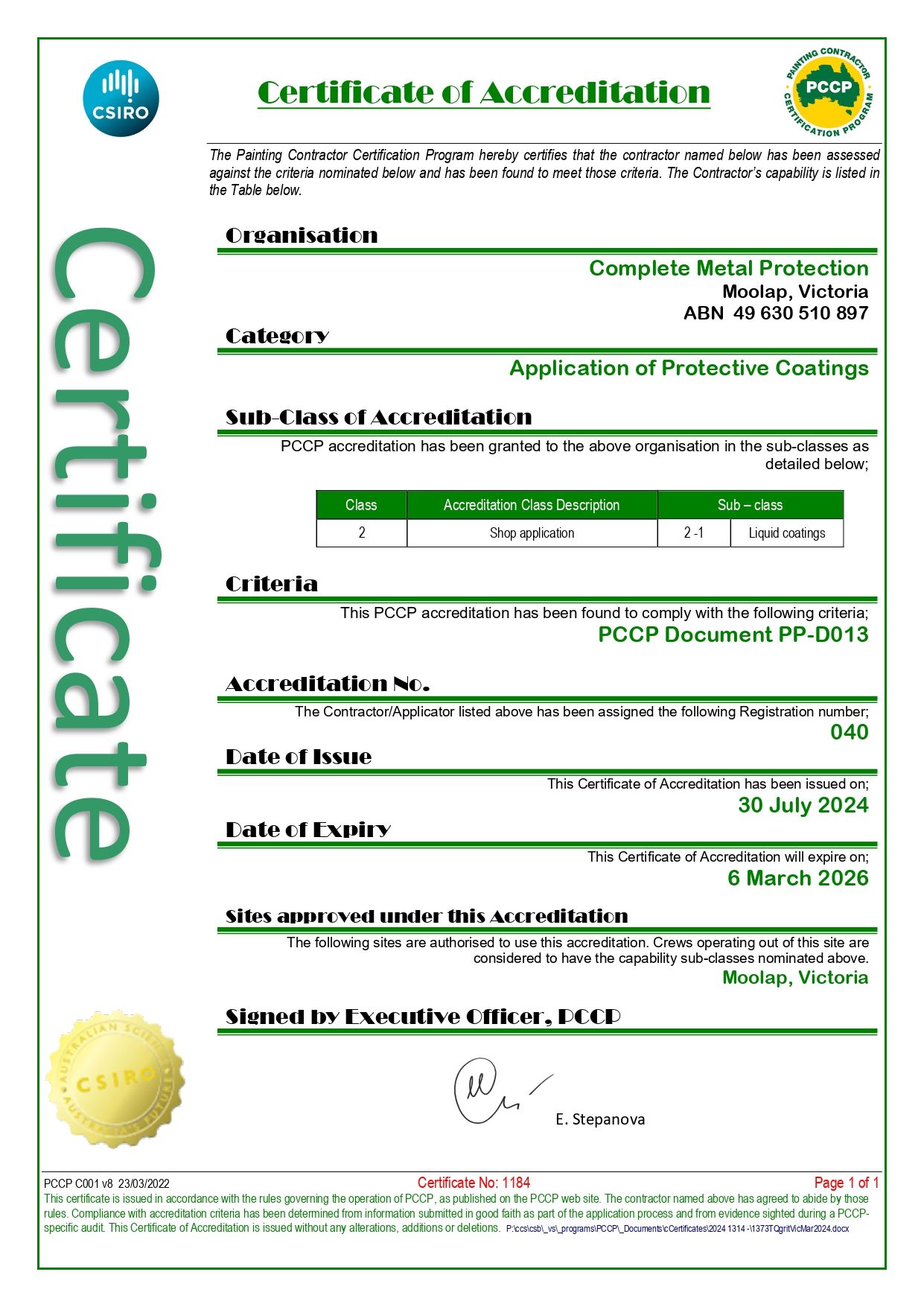

We are accredited to PCCP (Painting Contractor Certification Program) who perform regular audits on all areas of our operation.

Complete Metal Protection is a member of NACE International and has our own NACE Coating Inspector Level 1 – certified on staff.

We provide a variety of primer and coating services in Geelong for metal fabrications in the mining, marine, automotive and petrochemical industries, these include:

Complete Metal Protection is an approved applicator for:

Complete Metal Protection is a member of the Australian Corrosion Association. Contact us to find out more about our coating services for your next project.

At Complete Metal Protection, we are committed to delivering the best possible result for all our clients.

And that means we source the highest quality products from leading manufacturers across the globe to get the job done right.

Our suppliers devote extensive time and money to the research and development of protective coatings. They are at the cutting-edge in their field.

So when you are after protective coatings for your Melbourne project, you can rest assured that our team works with the best products on the market.

Our suppliers include:

We also forge strong links within the coatings industry, such as our membership with NACE International and accreditation with the Painting Contractor Certification Program.

If you would like more information about our line-up of suppliers, please contact us today. Don’t hesitate to ask our experienced team about our coating services and range of blasting services too.

Complete Metal Protection complete blasting and coating services for the following industries:

We aim to build and maintain strong relationships with our customers by providing the highest standards of quality, service and integrity.

We take quality seriously. Whether we’re working on a large scaled industrial abrasive sandblasting project or polyurethane spraying on a trailer, the high standard of workmanship we set is met by our team on every project.

Procedural systems are in place for all areas of our operations and our experienced, conscientious staff deliver the highest degree of workmanship.

All stages of the blasting & painting processes are closely monitored, inspected and tested to ensure all specifications are met and quality is of the highest standard.

We are accredited to PCCP (Painting Contractor Certification Program) who perform regular audits on all areas of our operation.

Complete Metal Protection is a member of NACE International and has our own NACE Coating Inspector Level 1 – certified on staff.

Complete Metal Protection is an approved applicator for:

We are a member for of the following organisations:

Complete Metal Protection has contributed to many projects throughout Victoria.

Some of the many projects we have been associated with during the past few years are:

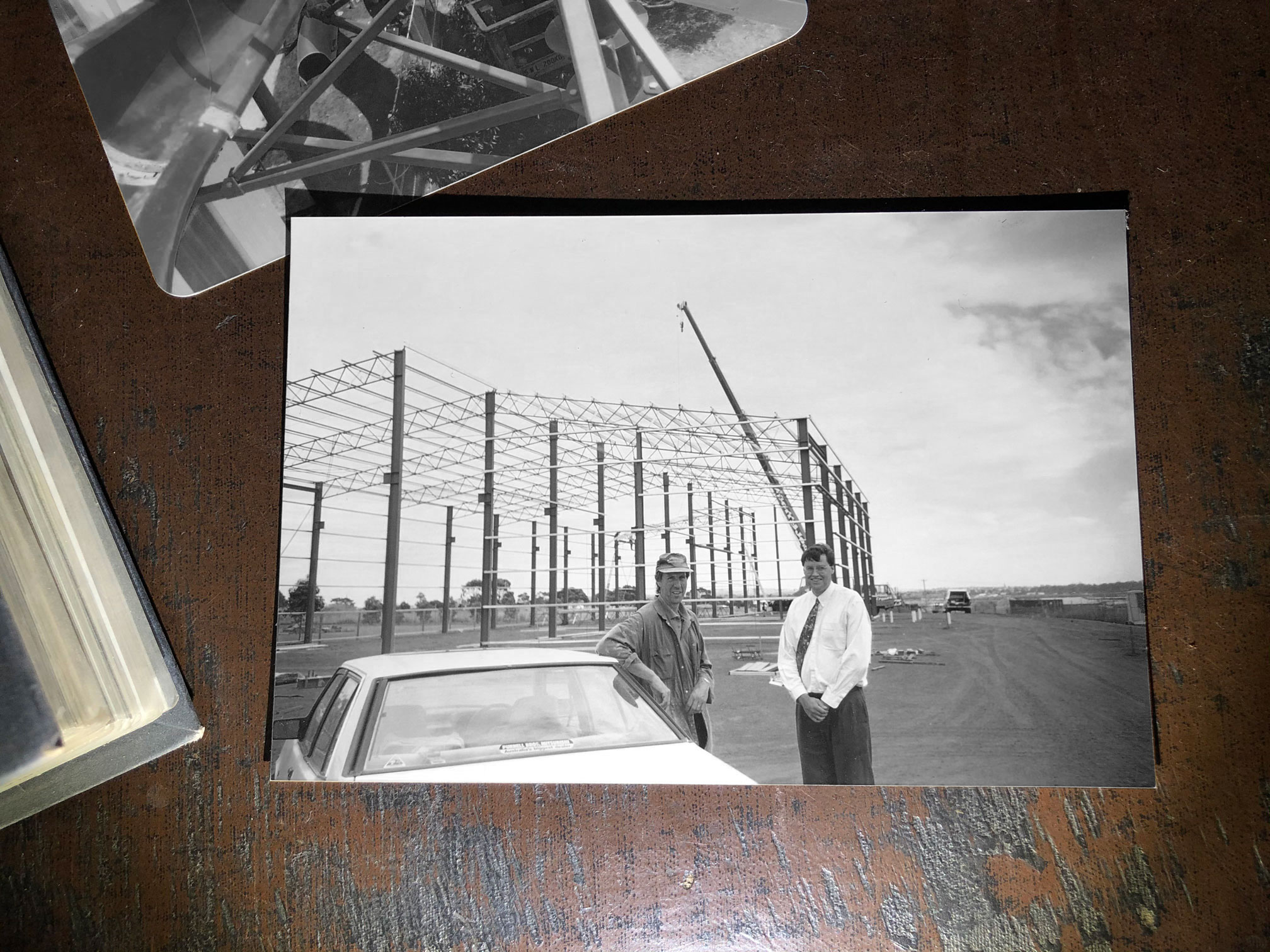

The business started in the early 1950’s as Fleming’s Painting. In 1961 sandblasting equipment was purchased and the business was based in Moolap, Geelong. It became known as Fleming’s Sandblasting. In 1997 the present premises was built in Buckley Grove, Moolap. In 2012, to convey our Company’s fundamental purpose we changed our trading name to Complete Metal Protection and moved into providing both blasting and coating services, from garnet blasting to epoxy coatings and the other services our clients depend upon today.

Our manufacturing site in Moolap, Geelong occupies over 2 acres.

With two abrasive blasting and two large paint sheds, we can handle large volumes effectively.

Two five tonne gantry cranes and a 12 tonne forklift mean we can handle very large steel fabrications. In addition we have a 5 tonne yard crane and two 2.5 tonne forklifts. We are well equipped to unload and load trucks efficiently and move work between blast and paint sheds.

Our larger blast and paint sheds can comfortably accommodate components up to 30m long. Even though we are geared up for large projects, we are small enough and flexible enough to manage specialized components with high tech requirements in small or large quantities.

We take quality seriously. All work is completed as per specification and our quality systems ensure that:

Complete Metal Protection’s alkyd enamel coatings offer Geelong and Victoria-wide business a multi purpose, high gloss coating that drys fast and is ideal for many steel structures and equipment. Our enamel coatings are applied to a primed surface by our experienced and highly proficient team, ensuring that the coating can do its job optimally.

Our high-quality enamel coatings are highly effective abrasives that protect the underlying surface from corrosion, rust and the elements, when applied by our team with proper surface preparation the coating will protect the surface for many years to come and will be unlikely to flake or break apart.

There are many reasons enamel coatings are a go-to for many industrial businesses, with the high gloss factor actively protecting the surface from dust, dirt and debris, as well as preventing the surface from being scratched.

Not to mention the fact that the smooth enamel surface allows for easy cleaning, making this an ideal coating for everything from piping to mining equipment and steel beams. The team at Complete Metal Protection have commitment to the highest quality of workmanship, which is why we only use the best possible coatings on the market that provide adequate protection for your steel fabrications.

Want to find out more about our enamel coating services in Geelong? We service clients Victoria-wide, from the mining industry to construction and more. Get in contact with our team to find out what kind of coating would be best for your project. We also provide polysiloxanes coating services.

Our Geelong-based team use epoxy coatings for clients primarily because of its ability to perform in both dry and wet environments on a variety of structures, from offshore oil rigs to bridge structures and pipes.

Unlike many other coatings, one of the benefits of epoxy is its ability to be applied effectively to a variety of surfaces from hand prepared rusty steel to surfaces that have undergone abrasive sandblasting and a range of existing and aged coatings (provided they are still intact).

Epoxy coatings are commonly mixed with zinc phosphate elements to make the steel structure resistant to corrosion and rust and suitable for wet conditions.

Complete Metal Protection have extensive experience in epoxy spraying for projects both big and small, working with businesses in the mining, shipping, petrochemical industries and much more.

When it comes to cost effectively protecting large metal fabrications both onshore and offshore you cannot go past epoxy coatings for durability and versatility. Our team ensure the coating is applied with expert precision on an adequately prepared surface.

Want to know more about our Geelong-based epoxy spraying services? Get in contact with our team today. If you’re looking for a fast-dry solution for steel coatings then our enamel coating service may be the right choice for you.

Our Geelong-based polysiloxane coating services are deigned to help provide ongoing protection to machinery, pipework, structural steel and much more. Polysiloxane coatings is also an ideal coating if you’re looking for high colour retention and a glossy surface that looks appealing whilst providing additional protection against corrosion and rust.

Polysiloxane is a highly versatile coating that can be used in a variety of extreme temperature environments, as well as being resistant to strong UV rays. This highly effective coating is also saves on application and maintenance costs, simply because you need less coats in comparison to a lot of other coatings.

A lot of these traits, combined with the fact that the coating has anti-graffiti properties and is proficient in protecting the underlying surface from dirt, makes polysiloxane coatings a popular choice for equipment, structures and fabrications that will be accessible to the general public.

If you’re looking for a durable and highly effective coating then polysiloxane coatings make sense in the long-term, economically, aesthetically and performance-wise. Polysiloxane coatings similar to the epoxy coating services provided at our Geelong HQ, are unrivalled when it comes to preventing corrosion – the primary function of any coating.

To find out more about our polysiloxane coating services for clients Victoria-wide please get in contact with our friendly and talented team.

Polyurethane protective coatings give businesses in Geelong and beyond an all-weather solution for both onshore and offshore equipment, vehicles and metal fabrications, highly resistant to extreme temperatures, high winds, salt water and precipitation.

Taking into consideration these factors, polyurethane coatings are well suited for use on equipment and fabrications used on offshore structure, in the petrochemical industry and on any surface that needs to be effectively protected from the elements, similar to our rich zinc primers.

The high gloss and smooth surface of polyurethane coatings mean that often dirt and other residue will be removed during rain, meaning this type of coating effectively cleans itself.

The high gloss components of polyurethane coatings combined with its ability to retain colour over time also makes it a popular choice for various types of machinery and transportation vehicles, giving them an attractive shiny finish.

When you deliver your equipment, fabrications, vehicle, trailer or pipework off at our coating shed for polyurethane spraying you can rest assured knowing you’re asset will be well protected and look state-of-the-art by the time our team we done with it.

Whether you have pipework that needs to be protected from all types of weather or a vehicle that you want to look eye-catching whilst being well protected, Complete Metal Protection will ensure you receive the highest quality of workmanship.

Our team also provide polysiloxane coating services in Geelong, ideal for those wanting additional protection against corrosion.

When it comes to protecting steel fabrications in harsh environments, a high-quality zinc rich primer applied in Geelong by our expert team becomes a necessity. So how does it work? Zinc rich primers play an important role in acting as a barrier between the environment, the top-level coating and the substrate. Zinc rich primers will actually slowly corrode underneath the surface coating to ensure the steel underneath remains intact.

The zinc particles in our zinc rich primer make them an ideal choice for many businesses working in the petrochemical and mining industries, due to their high effectiveness in protecting steel and metal fabrications from water, salt and other potential contaminants.

Similarly, inorganic Zinc Rich Coatings also provide excellent corrosion protection to a range of metal fabrications. The main difference between organic and inorganic zinc primers is the binders they use, organic zinc rich primers can be made with a range of binders with the main one being epoxy, whereas inorganic zinc rich primers primarily use a silicate binder. Complete Metal Protection provide our clients with both options. Inorganic zinc rich primers are generally difficult to apply and should only be done by specialists.

Complete Metal Protection is an approved applicator of some of the highest quality coatings and primers on the market, including Dulux Protective Coatings. To find out more about zinc primers contact our team. We also provide a variety of coating services, including polyurethane coating services at our Geelong headquarters.

Garnet is made up of Almandite and Andradite mineral deposits and is a slightly harsher material than glass bead blasting, for businesses in Geelong and beyond wanting a durable media that can be used with great accuracy.

Garnet is available in a variety of sizes, with the ability to use rough or more rounded edges depending on the desired result. Commonly used for preparing a range of surfaces for coating or industrial painting.

Due to its hardness – scoring between 7 and 8 on the Mohs scale – garnet is able to be recycled for repeated use, this combined with the fact that garnet abrasive blasting creates very little dust in comparison to other abrasive materials and is non-toxic, making it a suitable choice for companies looking for an environmentally friendly media.

These features also make garnet a cost effective material when it comes to abrasive blasting.

Another key advantage of garnet blasting for Geelong businesses is its versatility, with the ability for it to be used around water and in dry docks, tanks and other areas where other materials simply aren’t suitable.

Complete Metal Protection are garnet blasting experts, with the experience and skills to deliver high-quality, reliable results for businesses in the shipbuilding industry, petrochemical industry and many other industrial applications.

When it comes to carrying out any project big or small, Complete Metal Protection prioritises safety, the use of high-quality materials and equipment and unparalleled word class workmanship. Our clients throughout Victoria rely on us to deliver the desired result every time.

Contact us to find out more about our garnet blasting services, we also offer epoxy coatings, a got-to coating for ship-loaders, offshore oil rigs and more.

Glass bead blasting is a less abrasive method in comparison to other abrasive blasting materials commonly used by our Geelong team, including our sandblasting abrasive services. Glass beads offer a highly effective solution for removing materials such as paint or smoothing out surfaces that would otherwise be damaged by harsher abrasive blasting methods.

When you consider the multiple benefits that glass bead blasting offers businesses in terms of effectiveness, sustainability and cost, it’s no wonder this media is becoming increasingly popular when it comes to removing paint, rust and other coatings from a large range of industrial surfaces.

Glass bead blasting, similar to garnet blasting gives our Geelong and Victoria-wide clients an environmentally friendly and cheaper option for their abrasive blasting needs. The glass beads used in the blasting process are made up of recycled bottles and other glass materials, meaning the process is sustainable, non-toxic and less costly than other abrasive blasting materials.

Complete Metal Protection have extensive experience using glass bead blasting to effectively remove rust, coatings and paint from softer metal surfaces, as well as using blasting to smooth the surface of a range of metal fabrications. Our blasting shed allows us to operate on large-scale fabrications up to 30 metres in length.

We typically employ the use of glass bead blasting when working on projects in the automotive industry and other more delicate projects. When it comes to glass bead blasting services you simply cannot go past Complete Metal Protection, based in Geelong, servicing the whole of Victoria our clients range from multinational corporations in the petrochemical industry to small automotive businesses.

Not sure if glass beads are the right media for you abrasive blasting needs? Get in contact with the team at Complete Metal Protection.

Sandblasting is the most commonly used and referred to abrasive blasting technique, with its function mainly to remove coatings, paint, rust or other types of surface contaminants, along with it being used to shape metallic surfaces, either to make surfaces smoother or rougher.

Unlike our Geelong-based glass bead blasting services, our team use abrasive sandblasting for projects that require a deeper depth profile in the preparation for coating or painting, such as steel beams or to help combat rust and corrosion that occurs on metallic surfaces, structures and machinery.

Our team are specially trained to carry of highly effective and safe abrasive sandblasting in a variety of industrial applications. Silica sand (the common sand particles used in the process of sandblasting) can be toxic to humans if the proper safety precautions are not carried out properly, which is why it’s critical that you have the experienced and highly trained team at Complete Metal Protection carry out your abrasive sandblasting needs.

When assessing whether or not sandblasting is right for your project, there is many pros to take into consideration when making your decision. Some of the benefits of using abrasive sandblasting include:

Contact us to find out more about our Geelong-based abrasive sandblasting services, another popular service that we offer is garnet blasting.

Inorganic zinc coated facilities in Ballarat play a crucial role in ensuring that your steel protection needs are met. At Complete Metal Protection, we value and understand the significance of corrosion prevention.

Inorganic zinc coatings are made up mostly of metallic zinc dust and a high-performance binder. The result is enhanced steel corrosion resistance and increased weather resistance. We understand the importance of steel fortification and, with our inorganic zinc coated steel facility, not only have the capacity to satisfy your requirements, but also have the necessary the expertise and abilities to meet all demands.

Expert knowledge and extensive experience are required to be able to successfully execute metal protection. Complete Metal Protection is proud of the knowledge acquired through years of experience combined with continuous education and training.

Our work and relationship with our clients are a testimony of our experience and expertise.

Call us for your next industrial coating job. We look forward to speaking with you.

Geelong is a picturesque coastal city surrounded by the countryside and beautiful blue waters. While there are countless benefits of being near the seaside, an unfortunate downside is the impact of rust and corrosion.

Complete Metal Protection’s blast and grit Geelong service can help find a solution to your troubles.

Grit blasting is a process where particles (garnet) are rapidly directed against a surface. It is a method of utilising these sharp particles for abrasive cleaning or surface preparation. This technique involves impacting the surface with hard, angular particles traveling at high speed, which removes undesirable material from the surface, revealing a clear, functional metal surface. It addresses techniques for removing scale, rust, paint, and other surface films. These high-speed abrasive particles clean the material’s surface of impurities and prepare it for protective coatings.

It is important that the application is handled by a specialist with extensive experience and training. At Complete Metal Protection, we pride ourselves on our expertise, combined with ongoing education and training.

We stand by our work as testament to our skill and expertise. Contact us to discuss your next project.

Steel Priming in Melbourne is a crucial step in ensuring that the severe impacts of rust and corrosion will not affect your steel product. Steel that has undergone the process of being painted using a primer made of resin, additives, and solvents is referred to as primed steel.

Rust develops through the oxidation of exposed steel. This often occurs due to paint that adheres poorly to the bare steel surface, flaking off in huge chunks. Correctly prepared steel helps the paint adhere to the metal surface for a longer period of time, giving good adhesion. Priming also reduces the severity of imperfect surfaces on the steel product while also increasing steel’s resistance against corrosion through several components that are effective in cleaning, sealing, and protecting. The coating also increases steel’s passivity, which makes it more resistant to corrosion causing agents within the environment such as rain, humidity, and salt.

The theory behind this procedure is well understood, but execution requires a high level of proficiency.

Complete Metal Protection has the expertise and knowledge that comes from many years of experience and training. We stand behind our work and commitment to provide quality, service, and integrity.

Contact us to discuss your steel priming needs.

At Complete Metal Protection we understand the value of protective coatings for external structural steel in Melbourne. Preserving structural steelwork with the appropriate corrosion protection system will give a steel frame longer life and reduce ongoing expensive maintenance costs.

Steel is one of the most used materials for manufacturing buildings however, steel is also prone to rust in almost any environment especially when exposed to harsh conditions. To protect your building from rust and corrosion, it is important that structures are safeguarded through protective coatings. Knowing which protective coating will best suit your building is important to extend its lifetime. The challenges presenting by structural steel materials in salty air and severe environments require professional solutions and at Complete Metal Protection, that’s exactly what we offer.

Complete Metal Protection is the go-to protective coatings specialist in Melbourne and Geelong. We are proud of our strong client relationships, and we sustain this by upholding the highest levels of quality, service, and integrity. All facets of our operations have strict procedural standards in place and our trained employees provide the highest level of service.

Contact us to discuss the right solution for you.

Here at Complete Metal Protection, we understand the importance of being PCCP accredited in Geelong. Having PCCP accreditation ensures our client’s that they will receive the best kind of service with the utmost confidence in their chosen product partners.

The PCCP (Painting Contractors Certification Program) is an accreditation system for coatings industry contractors who seek to offer a way to strengthen and validate the professionalism and competency of their service. Started in 1992 as a mutual project between the Commonwealth (as a key owner of assets and infrastructure) and the industry, being PCCP accredited is an excellent approach to ensure that product owners of organisations and infrastructures can trust the services they have selected. A rigorous compliance system with performance standards that demonstrate the skills, knowledge, and experience in the industry is required to be PCCP accredited.

CMP is Geelong’s leading expert in corrosion prevention. Through the necessary training and skills, our team understands the best method for preventing corrosion and infrastructure degradation using organic coatings (paint). These coatings can offer 25 years or more of protection if selected and applied correctly. However, poorly designed, or improperly placed coatings can be a cause of failure in 12 months or less, needing costly maintenance or even the replacement of an asset. Millions of dollars are spent annually on useless maintenance procedures. It is extremely important to choose a partner that has the expertise and capabilities to ensure that this crucial job will be taken cared off efficiently.

Our PCCP accreditation is a testimony to our commitment to deliver the highest level of service to our partners and clients.

We take pride in the skills our team has earned from years of training and experience. Our work is a testimony of our ability and competence.

Contact us for your next organic coating job.

Here at Complete Metal Protection, we understand the value of being NACE accredited in Melbourne. Having NACE accreditation provides our clients, and the wider community, with the reassurance of our dedication to professional and responsible service delivery. We take our NACE accreditation very seriously. And we proudly display the NACE logo.

The National Association of Corrosion Engineers (NACE) is an organisation serving nearly 35,000 members in 130 countries and established globally as one of the premier authorities for corrosion control solutions. Being NACE accredited provides certifications that promote public safety and environmental protection while reducing the economic impact of corrosion.

For heavy engineering, structural steel, pipe work, and a variety of other fabrication industries, Complete Metal Protection is the go-to protective coatings specialist in Melbourne and Geelong. We establish and sustain strong client relationships by upholding the highest levels of quality, service, and integrity. All aspects of our operations have procedural standards in place and our skilled employees provide the highest level of service. Our NACE accreditation is a testament to our dedication to deliver the highest level of service to our partners and clients.

We take pride in the knowledge earned from years of experience paired with continuous education and training. We stand by our work as testimony of our ability and knowledge.

Contact us for your next industrial coating job.

At Complete Metal Protection we understand the importance of corrosion prevention. Our inorganic zinc coated steel facilities service Melbourne and will cater to your steel protection needs.

Metallic zinc dust and a high-performance binder are the main ingredients used to create inorganic zinc coatings. Advanced corrosion protection for steel and a greater resistance to harsh weather are the end result. Inorganic zinc coatings are used for a variety of applications, including bridges, pipework, and steel. We recognise the significance of steel fortification and not only have the capacity through our inorganic zinc coated steel facility to cater to your requirements but also have the necessary expertise and skills to meet all specifications.

Although the theory behind this method is widely understood, application requires expert knowledge and skill. At Complete Metal Protection, we take pride in the knowledge gained from years of experience paired with continuous education and training.

We stand by our work as testimony of our ability and knowledge.

Contact us for your next industrial coating job.

Melbourne’s beautiful bay side setting has many advantages; seaside living comes with some unwanted side effects. Severe impacts of rust and corrosion are a common effect of the salty air.

Complete Metal Protection’s Metal Priming services in Melbourne can help you find a solution to your problems.

Primed steel is prepared via the application of a primer or undercoat prior to painting. This application acts as a bonding agent that allows the paint to better adhere to metal. Primers contain several components that are effective in cleansing, sealing, and safeguarding metal. As a result, this procedure improves the coating’s adhesion to the surface, providing extra protection for the steel.

The coating increases metal’s passivity, which makes it more resistant to corrosion-causing agents in the environment such as salt, rain, and humidity. Primed steel aids in the prevention of corrosion and oxidation and greatly improves the life of the material.

Although the theory behind this procedure is understood the execution requires a high level of expertise. Complete Metal Protection has the expertise and knowledge that comes from years of experience and training. We stand behind our work and commitment to provide quality, service, and integrity. Contact us to discuss metal priming needs.

Geelong enjoys many benefits of being near the seaside, but an unfortunate downside of the salty air is the extreme effects of rust and corrosion.

Complete Metal Protection’s Grit Blasting in Geelong can help with a solution to your woes.

Exposure to water and the salt air are factors that will reduce the service life of metal equipment in this tough Australian environment. When a metal surface has corroded and rust and other contaminants have started to take effect, the first step to reinstating the metal into a presentable and protected form is the removal of the rust. Grit blasting is a process where abrasive particles are vigorously directed against a surface. These high-speed abrasive particles remove contaminants from the material’s surface and condition the surface for subsequent finishing. Different variants of the blasting process involve different methods, which range in their levels of abrasiveness, some being highly abrasive while others are very mild.

The science behind this process is well understood, however, the application requires specialist knowledge and expert technique. At Complete Metal Protection, we pride ourselves on the expertise that experience, combined with ongoing education and training brings.

We stand by our work as testament to our skill and expertise.

Contact us to discuss your next project.

Before

Blast and prime services for Ballarat have provided long lasting metal protection for decades.

Traditionally, sandblasting was the ‘go to’ option for abrasive blasting. First patented way back in 1870, the process is still very effective at removing coatings, paint, rust and corrosion from metal surfaces. It is a particularly abrasive method of blasting and can be used to shape metal – creating either a smoother or rougher finish.

Newer methods of abrasive blasting such as Garnet and Glass Bead blasting, offer the benefits of sandblasting and more. By selecting the appropriate media and method based on the desired result, we are able to precisely control the process and the outcome. Rather than blasting an entire surface, we can very accurately blast section by section if needed. We can offer much improved environmental and safety outcomes and, as the media can be recycled and used again, the newer methods can prove more affordable.

Once a surface has been prepared, it will require a coating for protection. Step one is the prime. A zinc rich primer is an ideal choice for the most demanding of conditions. Zinc primers are offered in organic and inorganic. The difference between the two comes down to the binders used. Organic can be made with a range of binders, with the most used binder being epoxy, while inorganic primers use a silicate binder.

As you can see, there are a number of variables to consider for a blast and prime to ensure the best result. At Complete Metal Protection, we like to focus on the word ‘complete’ as a key part of our mantra. Our promise to you is that our service is ‘complete’. And that starts with complete advice and guidance specific to your project. Get in touch to discuss how we can help select the best options for you. We’ll look forward to hearing from you.

Demand for industrial inorganic zinc coated steel in Ballarat is high as construction remains busy in challenging times. Inorganic zinc rich coatings in combination with silicate binders, deliver outstanding corrosion protection to metal as they react with the atmospheric carbon dioxide. This process, called silicification, reacts with substrates, chemically bonding to the surface rather than just placing a covering over it. In addition to delivering a sustainable solution, this process offers impressive fire resistance, UV protection, vapor permeability and durability.

The chemical bond between the metal surface and the coating is very strong, and is permanent, ensuring long term protection even in extreme environmental conditions.

The science behind this process is well understood, however, the application requires specialist knowledge and expert technique. We have been delivering inorganic zinc coatings to jobs across Victoria since the 1950’s – not all that long after Victor Nightingall patented the process in 1937. At Complete Metal Protection, we pride ourselves on the expertise that experience, combined with ongoing education and training brings.

We stand by our work as testament to our skill and expertise.

Contact us to discuss your next project.

Since it’s invention in the 1930’s epoxy coatings have been widely utilised to protect metal surfaces, and here at Complete Metal Protection in Geelong, we have been experts in the application of epoxies since the 1950’s. But how do we go about protecting epoxy coatings and why would we need it?

This system offers an excellent long-term solution for a wide range of demanding situations. After some time in the elements the surface of the coating will begin to lose its gloss and visual appeal. This is a normal part of the process and presents no issue to the protective qualities of the coatings. Aesthetically, however, the loss of gloss which, with time, will give way to a chalkiness on the surface of the paint is likely to be an issue in situations where presentation is important.

To prevent this scenario, we have 2 top-coat options, polyurethane and polysiloxane.

Both provide high gloss, hard wearing protection from UV light and the elements, and will enable colours to remain bright and strong for long term allure. The smooth shinny finish is almost self-cleaning as even a moderately heavy rain shower will clear the surface of dust and debris.

Polyurethane is often selected for applications ranging from domestic through to plant and equipment, and offshore use. These situations can be very testing environments and stand as a testament to the effectiveness of polyurethane.

For commercial situations requiring protection due to exceptionally high use, such as train stations and public access areas, polysiloxane is often utilised. Polysiloxane lifts the bar on toughness and long-term wear and tear. It provides an exceptionally hard finish and outstanding protection for bright colours. Boasting 10 to 15 years of durability until first maintenance. Polysiloxane is often the preferred choice for government owned assets.

At Complete Metal Protection we take pride in all that we do.

Our knowledge is complete, as is our professionalism, and we’re here to help complete your next project. Contact us to discuss the right protective coating for your needs. We’ll look forward to speaking with you.

Having established our business way back in the 1950’s Complete Metal Protection has provided skill and expertise to a good number of significant projects. If you were to tour our state, you might be surprised to learn how many iconic scenes feature our work. But that never reduces our aim to be involved with new and exciting projects large or small. It was with great pride that we were able to supply our services to the new GMHBA head office in Geelong.

Our role was to provide protection to the outriggers that feature on the external faces of the building. To achieve the ultimate protection and design specifications we employed a 3 coat external paint system.

The first coat utilised a zinc rich epoxy for long term, hard wearing protection against corrosive properties. The intermediate coat is a high build, high solid epoxy coating which resulted in a barrier to the natural environment. And finally, the topcoat is a polyurethane, which not only sets the work off with a high gloss finish, but also provides protection, including from UV, to the lower coats, preventing chalking and delivering a long term quality finish.

This new Geelong icon sits proudly in Moorabool street, the heart of the CBD. A CBD that has experienced significant development and modernisation over recent decades. At Complete Metal Protection we are delighted to have once again played our part.

No matter the project, large or small, iconic or not, if you’re after metal coatings get in touch, we’d love to speak with you.

The Bellarine Peninsula has seen enormous growth over the last few years. And rightly so! The opportunities on offer to enjoy a seaside destination lifestyle are seemingly endless. Infrastructure is on the move enabling easier access and better facilities. Businesses are investing – offering more goods & services – from fine dining to hardware and banking to sporting goods. People of all ages and backgrounds, from first home buyers to retirees are making the Bellarine home.

Whether you’re sitting high on a hill with a coastal view, or walking distance from the beach, the risk to metal assets from salty air on the Bellarine is ever present and should be dealt with professionally and thoroughly. Science tells us that humid ocean air corrodes 10 times faster than normal humidity and is significantly more damaging than standard rust. (ref: https://sciencing.com/effects-saltwater-metals-8632636.html) So, it stands to reason that your metal protection should be 10 times more thorough!

At Complete Metal Protection being 10 times more thorough than our competitors is certainly our aim! We specialise in epoxy coatings, zinc rich and zinc phosphate elements creating outstanding protective coatings for surfaces in salty conditions.

Our focus on professionalism ensures all stages of our processes are inspected and tested to meet or exceed all specifications and expectations.

Accredited to PCCP (Painting Contractor Certification Program) we are regularly audited, providing our customers with the assurance of the highest standards at all times.

The challenges presenting by metal surfaces in salty air require professional solutions. And at Complete Metal Protection, that’s precisely what you’ll get! Contact us to discuss the right solution for you.

The alure of coastal living is undeniable. Breathtaking views. Fresh sea air. Sand between the toes. Beach towels drying on the railing.

But the beauty and relaxation mask a tough environment.

The mix of salt, oxygen and moisture along the surf coast is extremely corrosive. The damage to metal from this mixture is worse than the standard effects of rust, causing the metal to literally fall apart. Humid ocean air corrodes 10 times faster than normal humidity. (ref: https://sciencing.com/effects-saltwater-metals-8632636.html)

But it is certainly not all doom and gloom! The science and technical developments over the hundreds of years of metal being utilised in coastal settings, have equipped us with the knowledge, techniques and chemical expertise to ensure long term durable protection. Durable metal coatings for seaside settings have come a long way!

We offer the right solution for each challenge, often applying zinc rich or zinc phosphate epoxy coatings to safeguard not only the asset – but the lifelong dream of seaside living.

At Complete Metal Protection, we are about long term, durable solutions for metal structures and we’re here to discuss your project. We look forward to speaking with you.

Complete Metal Protection. Complete Professionalism. Complete Knowledge. Complete Satisfaction. Get in touch now.

Braeside Park, located in Melbourne’s southeast suburbs, is a picturesque green-space oasis with a wide selection of leisure opportunities. The park is home to a diverse variety of plants, birds, and reptiles, as well as important environmental and cultural heritage. Parks Victoria’s strategy recognises the value of park conservation while also creating opportunities for all residents to enjoy them. And key to that enjoyment is ease of access!

Complete Metal Protection had the privilege to work with Major Road Projects Victoria and Aus Group on the completion of the Pedestrian Underpass at Breaside Park. A well-lighted, 6-metre-wide pedestrian underpass was built to preserve the vital connection to the Woodlands Industrial Estate. The fences were improved to be longer and taller with the goal of minimising the impact to local wildlife.

CMP advised pre-project regarding paint systems and project schedules, before providing a Class 1 blast (whip) over galvanised steel. Operating to VicRoads specifications, we utilised a Dulux paint system, priming in Durebild STE and finishing with a Weathermax HBR top coat in a striking lobster red.

As we always strive to do, and as a part of our ‘Complete Service’ mantra, the project was delivered on time and on budget with packing cured product to minimise transport damage.

We are delighted with the result and proud to help the public to easily access this native haven.

If you are looking for blasting and protective coating services, please get in touch, we’ll look forward to discussing your next project.

“Good evening, and welcome to television.” Those were the faithful words delivered in 1956 by Bruce Gyngell, announcing the launch of television broadcasting in Australia. Modern wonders were sweeping across the world, in some cases literally, Electroluxes were cleaning our floors, and homes were filled with bulky, round shouldered appliances!

The 50’s saw a driving revolution too, with many Australians driving Ford Customlines and FJ Sedans, created by a small, now defunct, company called Holden. You may have heard of them! Who’d have thought!

Fashion was on the move too – with rock and roll not only on the airwaves but establishing its own look! And of course, its own king!

Also established in the 1950’s, but unlike Holden still standing strong, were the beginnings of Complete Metal Protection. Back then we were Flemings Painting (& yes, we have checked, there is no relation to Ian Fleming of James Bond fame, who was also very busy in the 50’s!).

Unlike today, back in the 50’s Geelong was a tad isolated from the rest of the state and our contribution to the decade’s incredible growth and prosperity was to provide the most thorough and professional paintwork on offer in the region. There is no better way for a business to continue to thrive for such a long period.

Over time we expanded our services to provide both blasting and coating options.

As our offerings became more focused on ‘complete’ solutions, we also changed our name to Complete Metal Protection.

Today, our experience in blasting and coatings is second to none.

CMP’s Garnet and Glass Bead Abrasive techniques each suit different applications and client needs enabling us to provide the appropriate service for your requirements.

Protecting metal is what we do. And we do it completely. Thorough protection starts with surface preparation and finishes with coatings that meet specification.

Being accredited to PCCP (Painting Contractor Certification Program) CMP is regularly audited to ensure all standards are met. Complete Metal Protection is also a member of NACE International, and we have our own NACE Coating Inspector Level 1 – certified on staff.

At CMP our experience is complete, and we’re here to help complete your next project. Contact us to discuss how we can get you started.

At Complete Metal Protection (CMP) in Geelong, we’re not just about providing our customers with world standard blasting and coating services, we’re about complete professionalism, complete reliability and complete service.

CMP is a vibrant modern business. And while we celebrate our long and proud history, we believe our past does not entitle us to a future. We are never complacent and always strive to be a complete business.

We take pride in all that we do and every interaction we have.

Our goal is to deliver complete quality, complete reliability, complete service and complete value, and all with compete integrity.

We take comfort in the knowledge that this outlook provides our clients with a greater level of professionalism every time, returning a better ROI.

At Complete Metal Protection, we deliver complete satisfaction.

Get in touch with us to discuss how we can help you to complete your next project.

The coastal environment around Geelong and surrounds can be as harsh as it is beautiful. The weather extremes from glorious sunshine to beating rain, from the hottest of days to the coolest, merged with occasional high wind speeds and that oh so corrosive salty air, mean that durable coastal coatings for metal surfaces are essential for long term protection.

After hundreds of years of metals being used in extreme marine environments the science behind superior performance corrosion resistant coatings has come a long way.

The benefits of epoxy coatings in such applications are significant. Often combined with zinc rich or zinc phosphate elements, these coatings provide outstanding resistance to rust and corrosion and are well suited to wet and salty conditions.

The team at CMP offer complete professional standards and extensive expertise in the preparation for, and the application of epoxy coatings for such situations.

The CMP team will advise you on the right solutions for your project, contact us for more information.

Do you have a large steel metal plates that are in need of quick and professional inorganic zinc coatings in Melbourne? We at Complete Metal Protection (CMP) have the experience, industry expertise and large facilities to get the job done and exceed far beyond client expectation.

The process of coating metal plates, and other forms of metal with inorganic zinc protects the steelwork from the ravages of corrosion. Our team of seasoned experts regularly undertake this job, in order to shield steel from high temperature and abrasion, whilst ensuring the durability and longevity of the steel.

No matter how big or small your job is, the Complete Metal Protection team can assist you. Our large blasting and coating facilities based in Moolap, Geelong spanning over 2 acres allow us to work on projects of all sizes. We have an extensive range of equipment, thorough safety measures and our team of experts are qualified to complete the job to the highest standard of quality with unmatched turn-around times.

Servicing the whole of Victoria, We at Complete Metal Protection have a strong commitment to customer service, quality and ensure optimum durability and performance. Contact us today on (03) 5248 2021 to learn more about our professional and industry leading inorganic zinc steel coating services for large metal plates in Melbourne. We look forward hearing from you.

Check out our most recent video regarding an inorganic zinc steel coating project for large metal plates which included a process of blasting, priming and rolling to build diesel tanks in Melbourne.

We recently undertook a project of applying a premium protective coating system in 2 coats. This job was with a major Melbourne fabricator that is part of the level crossing removal project in Melbourne. This is using an acrylic polysiloxane, Interfine® 979. This product provides a high performance, two-component, high solids inorganic hybrid finish which contains no free isocyanates. In plain English, this provides quality long term protection with a relatively quick turn around time.

The system we used was a 2 coat system of Zinc rich epoxy primer (Interzinc 52) with a Polysiloxane topcoat Interfine 979.

This application provides:

With ou large blasting and coating facilities in Geelong coupled with our quality workmanship, we are able to work with a large variety of metal coating systems. This 2 coat system enabled a fast turn around time to our client’s time frames to a Melbourne location. If you are looking for a steel coating system where the finished product is a visual part of the construction you need to consider this system. Industrial and commercial steelwork, (architectural steelwork), bridges and offshore structures are just some of the useful applications.

Call us at Complete Metal Protection. Large industrial blasting and coatings capacity.

Are you a fabricator in Melbourne, Geelong, Ballarat or Bendigo and looking for a qualified blasting and coating business that can assist with:

Complete Metal Protection (CMP) has been in the abrasive blasting and coating industry since 1986. That’s a lot of experience in any language. They have worked with just about every protective coating system there is. CMP simply don’t rest on there acquired skill sets gained from working in the industry for such a long time it’s also working with quality products such as:

At CMP we pride ourselves on industry-based training for our employees and our blasting and coating industry-recognised accreditations:

The NACE Coating Inspector Program is considered by many to be the coating inspection industry benchmark for inspections in the protective coatings industry.

If you are a metal fabricator and would like to make a time to discuss what we can do for you, please Ben Pascoe our Managing Director now on 03 5248 2021 to discuss your blasting and coating requirements.

Looking to finalise that car project you have been working on? Need to get that blasting done so you can finally get that respray done. Do you need to get around to blasting and coating your ute tray? These are some of the smaller jobs we can do here in Geelong. The gallery below showcases some of the recent abrasive blasting and coating work we have done here at Complete Metal protection (CMP). Many people refer to sandblasting but modern techniques mean that sandblasting may not be the best suit blasting technique for your project.

No job too small and our large yard makes access, easy and accessible. We have two purpose-built facilities at CMP, one for those industrial-sized jobs for steel fabricators, the other for smaller one-off projects.

At Complete Metal Protection we recently had the privilege of working with Hanlon Industries on the restoration of the Jetstar sign at Avalon Airport. This particular job is an excellent example of the fact that not all protective coating systems are the same. We would expect this project to last for 10 to 15 years before it needs to be refreshed. Upon our initial inspection, we discovered heavy pitted rusting in many of the girders. Pitted rusting, even after a sustained period, is not typical for a job that has been completed using the correct coating system.

The environment and elements at Avalon Airport can be extreme. The elements go from the extreme temperatures of the mid-forties in summer to low single-digit figures in winter. The temperature extremes do not take into account the high-velocity winds and the salt air coming in from Corio bay. This means that any steel exposed to the elements needs to have an exceptionally high-quality coating system.

For this particular project, Hanlon Industries were very specific in providing a quality solution for their client and nominated the following three coat system.

The results speak for themself and will continue to do so for a good ten to fifteen years. To restore the signage is a fraction of the cost of replacing yet is now as good as new and better protected to face the elements. It’s not about merely providing a coating service. First, you have to understand the purpose of the steel, and what it is going to be used for, then you need to understand the elements that the steel will be subjected to. Once you have understood the factors impacting the project at hand, can you then develop the most appropriate steel coating system?

The Jetstar Avalon signage required long-lasting outdoor steel signage that is to be subjected to extreme temperatures and salt air corrosion as well. At Complete Metal Protection, we are incredibly proud of our team and the job completed.

Complete Metal Protection (CMP) recently worked on this exciting new development for the Essendon and Penleigh Grammar school (PEGS) – sports centre. The builder for this project was McCorkells and the client was Vic Structural. CMP worked closely with Sherwin-Williams Protective Marine Coatings for the specific coatings for this project.

Our brief was to coat the structural steel in accordance with the architectural requirements.

The following elements were used as part of the process in providing the required steel treated and coated to exacting specifications for this project

At CMP 3 core elements are at the core of each project we undertake.

Preparation. For PEGS we checked for mill scale, rust and oil, grease fat perspiration. And where applicable attention was paid to welds and the adjacent areas. All mild steels had both a pretreatment and surface preparation prior to applying the applicable coatings.

Quality coating materials. This goes without saying. For this specific job we worked with Sherwin-Williams Protective Marine Coatings

Quality craftsmanship and the skill of our workforce. At CMP we have firmly believe in building a reputation rather than relying on one.

At Complete Metal Protection (CMP) our large facilities mean we have the capacity for those large industrial inorganic zinc coated steel jobs.

When looking to treat steel with corrosion resistance (rust resistant) properties for those larger commercial jobs you can opt for hot dipped galvanized steel or inorganic zinc painted steel. Both treatments come in at a comparable price and both rely on metallic zinc for their corrosion resistance properties. However it’s in the application of the coating where the differences take place. Without going into the technicalities,a US coatings blog states under many difficult corrosion conditions, the inorganic zinc coating will have a much longer life than the galvanizing under the same conditions. Another issue that may present for hot dipped galvanized steel is warping of the steel during the hot dipping process.

Without a doubt inorganic zinc primers would appear to win the day as the hot dipped galvanizing process just does not offer the same abrasive and chemical protection.

The image attached is from a job CMP did for GFC Industries, the builder was Multiplex at 80 Collins Street.

Industrail inorganic zinc primers are just some of the jobs we can do for you at CMP, we also work with enamels and epoxy coatings amongst others. Call us now for you next large industrial coating job.

The Portarlington Cricket club came to Complete Metal Protection (CMP) to ask if we could help them out by grit blasting and painting with protective coatings their newly acquired sight screens.

Whilst small jobs like this is not something we focus on it was definitely something we could help with. This environment (marine, salt air, coastal) can be incredibly damaging to metals and materials prone to corrosion. They needed a solution that is durable and will survive the elements.

After discussion about the location of their oval, exposure to the marine and salt air environment and what they were wanting regarding service life for their metal equipment exposed to this harsh Australian environment we decide to go with a 3 coat system after the initial grit blasting.

The 3 coat system is ideal for protection against the specific elements in a coastal town like Portarlington on the Bellarine Peninsula in Victoria.

3 coating system (2 coat epoxy, 1 polyurethane) for marine and salt air environments

1. Interzinc 52 Zinc rich epoxy providing anodic protection

2. intermediate coat of Interplus 1180 high build epoxy providing barrier protection of prime coat

3. Last of all is Interthane 870 (satin) Polyurethane providing excellent UV protection.

This 3 coat paint system will provide excellent durability to the harsh marine environment. This coating will provide a minimum of ten years and up to 15 years until the first service is required.

Whilst the cricket screens are a small job in the scheme of things this treatment is typical of architectural and larger engineering projects that are exposed to a salt air and coastal environment. As you can see from the images below we are really geared up for much larger industrial jobs but we must say it was our pleasure to work with the Portarlington Cricket Club.

Complete Metal Protection recently worked on the Club Jubilee One Aquatic Centre and Gymnasium in Wyndham Vale. Abrasive sandblasting and coating is being used as per the appropriate paint specification. The construction of the new aquatic centre features a 25m lap pool, leisure/toddlers pool, waterslides and other areas include basement plant room, change rooms, gym and lobby areas. High build general purpose epoxy zinc phosphate primer, an epoxy coating and a recoatable satin polyurethane finish, all completed in our Geelong facility.

Aquatic centre construction requires specific paint specifications for the fabricated steel to resist the corrosive elements and environment. This was a great job to work with as the paint specifications were as much about the protection as they are for the architectural steel aesthetics. We worked with Stilcon Holdings and McCorkell Constructions on this project.

We used a 3 coat system based Dulux products

Looking for professional and reliable abrasive blasting and coating services? Get in contact with the friendly and professional team at Complete Metal Protection. We work on a range of industrial and commercial projects.

Complete Metal Protection carried out blasting and our coating service on the Geelong Ring Road noise wall. This project was staged over many years, 2007/08 & 2010/11 & 2014, CMP painted to a rigid paint specification for the protection of the supporting members of the noise wall.

Complete Metal Protection (CMP) recently worked on this exciting new development for the Essendon and Penleigh Grammar school (PEGS) – sports centre. The builder for this project was McCorkells and the client was Vic Structural. CMP worked closely with Sherwin-Williams Protective Marine Coatings for the specific coatings for this project.

Our brief was to coat the structural steel in accordance with the architectural requirements.

The following elements were used as part of the process in providing the required steel treated and coated to exacting specifications for this project

At CMP 3 core elements are at the core of each project we undertake.

Preparation. For PEGS we checked for mill scale, rust and oil, grease fat perspiration. And where applicable attention was paid to welds and the adjacent areas. All mild steels had both a pretreatment and surface preparation prior to applying the applicable coatings.

Quality coating materials. This goes without saying. For this specific job we worked with Sherwin-Williams Protective Marine Coatings

Quality craftsmanship and the skill of our workforce. At CMP we have firmly believe in building a reputation rather than relying on one.